i400 Intelligent Laboratory Pump

PERISTALTIC FLUID DELIVERY SYSTEM

POWERFUL.

FLEXIBLE.

INTUITIVE.

i400 Intelligent Laboratory Pump

PERISTALTIC FLUID DELIVERY SYSTEM

POWERFUL. FLEXIBLE. INTUITIVE.

Introducing the FLUIDLINK i400 Intelligent Laboratory Pump

Bringing unprecedented control over the most demanding fluid delivery processes. Experience the i400, acclaimed for it’s compact size, feature-rich and cleverly simplified user interface, with unmatched automation connectivity. Our industry-driven design and operator-focused engineering deliver the tools you need to convert your greatest process challenges into a seamless multidimensional workflow.

INTELLIGENT

A PUMP WITH A MIND OF ITS OWN

The i400 delivers dozens of features, most never before seen in a laboratory pump - features only made possible by the combination of expert engineering, powerful software design, and the industry’s most advanced pump controller architecture.

NOTABLE FEATURES INCLUDE:

Programmable Delivery Routines

Unlimited Scheduling - run multiple independent schedule-driven dispensing sequences, and trigger any series of linked sequences for infinite possibilities.

Instant "Go-To Flow Rate"

Instant “Go To Flow Rate” - immediate delivery of a precise flow rate without ramping or waiting on weight scale feedback.

Stored Tubing Calibrations

The i400 stores an unlimited quantity of both factory-installed and user-created tubing calibrations.

Seamless Scale Integration

Connect a laboratory weight scale to enable a multitude of performance enhancing and time saving features unique to the FLUIDLINK line of products.

Turn the i400’s touchscreen into an operator interface for your scale! Using “headless” scales (without a bulky display or button interface) greatly reduces costs, and lets you reclaim a significant amount of useable benchtop space.

Mixed-Mode Operation

The i400 is the only laboratory pump that supports simultaneous mixed-mode operation for Attended, Industrial, and Remote modes - right out of the box!

Industrial Networking

Modbus RTU, Modbus TCP/IP, and EtherNet/IP (Industrial Protocol) come built-in, and future software updates will enable the same hardware to support additional protocols - at no additional cost.

Remote Control

Operate the i400 from anywhere, via a secure web browser connection to the FLUIDLINK Cloud. Enjoy 24/7 remote access to start, stop, and monitor your pump’s activity, all while saving inconvenient trips to the lab on weekends and after hours.

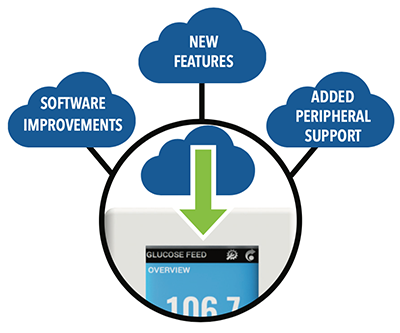

Software Updates

The FLUIDLINK line of products employ state-of-the-art functionality that’s years ahead of the competition, however, even the best products have room for improvement. That’s why the i400 Operating System can be updated right over the internet. This powerful feature allows you to take advantage of newly added functionality, and brings future support for an emerging market of 3rd-party peripherals.

Multilingual Support

Language localization for English, Deutsch, French, and Spanish.

The i400 approaches every feature of a peristaltic pump with a fresh perspective, maintaining the goal of making the operators work easier, faster, and more accurate. Everything from simple priming to even the most advanced dosing strategies is made more effortless by a powerful yet intuitive user interface.

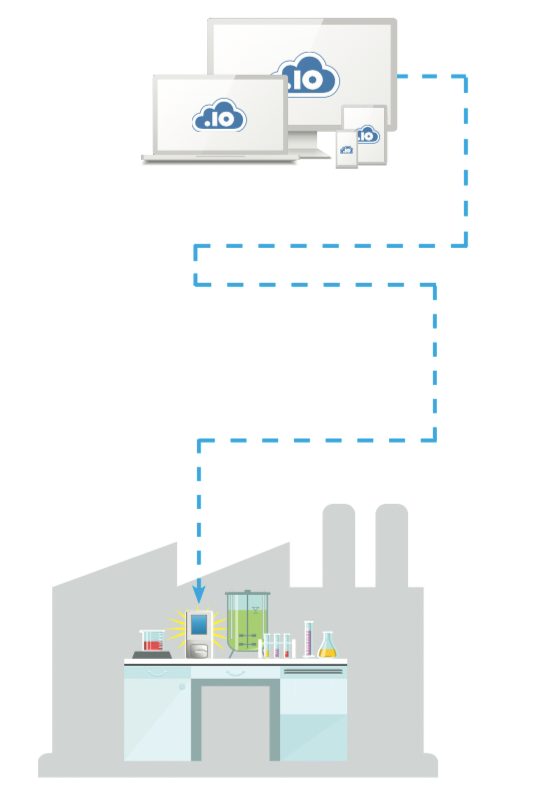

REMOTE CONTROL

SAVE A TRIP TO THE LAB WITH FLUIDLINK.IO

Operate the i400 from anywhere, via a secure web browser connection to the FLUIDLINK® Cloud. Enjoy 24/7 remote access to start, stop, and monitor your pump’s activity, all while saving inconvenient trips to the lab on weekends and after hours.

By combining FLUIDLINK.IO connectivity and the i400’s ability to use an integrated scale, you’ll be able to view your supply levels from anywhere. Use the Alarm and Notification features of FLUIDLINK.IO to proactively alert you when it’s time to replenish your fluid supply, and ensure uninterrupted delivery.

The online tools at FLUIDLINK.IO allow you to author, launch, and manage dispensing sequences, and perform numerous other tasks as you would when interacting directly with the local touch screen interface. Use the online tools to distribute copies of saved dispensing sequences from one pump to another, allowing you to easily duplicate complex instructions from one i400 to all the pumps in your lab.

CONNECTED

INDUSTRIAL NETWORKING BUILT-IN

The i400 is the only laboratory pump that supports simultaneous mixed-mode operation for Attended, Industrial, and Remote modes - right out of the box!

Modbus RTU, Modbus TCP/IP, and EtherNet/IP (Industrial Protocol) come built-in, and future software updates will enable the same hardware to support additional protocols - at no additional cost. Network connections are made via waterproof ports in the rear of the device, and the product ships with a set of male connectors to make installation a breeze.

Each operating mode delivers the full range of speed, flow, and dosing control, all without compromising control resolution (unlike outdated 4-20 mA solutions).

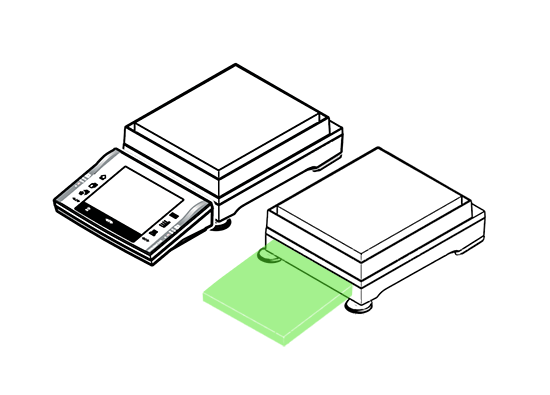

SCALE INTEGRATION

UNPARALLELED ACCURACY - REDUCED COSTS - SMALLER FOOTPRINT

Connect a laboratory weight scale* to enable a multitude of performance enhancing and time saving features unique to the FLUIDLINK line of products.

Turn the i400’s touchscreen into an operator interface for your scale! Using “headless” scales (without a bulky display or button interface) greatly reduces costs, and lets you reclaim a significant amount of useable benchtop space.

Save bench space with headless scales.

The i400 stores an unlimited quantity of both factory-installed and user-created tubing calibrations, but operates with even greater delivery accuracy when linked to a dedicated weight scale. Use of an integrated scale enables a number of exclusive features, including:

“One-Step Calibration” - The easiest way to create a unique tubing calibration! Leave the i400 unattended as it executes a series of complex calibration routines, all with the simple press of a few buttons.

“Disruption Dampening” - Prevent accidental operator disruptions from creating unwanted interference with your scale measurement. The i400 employs a proprietary disruption dampening algorithm that filters out bad readings caused by accidental bumps.

*Weight scale must support MT-SICS Command Protocol and be equipped with an RS-232 communications interface.

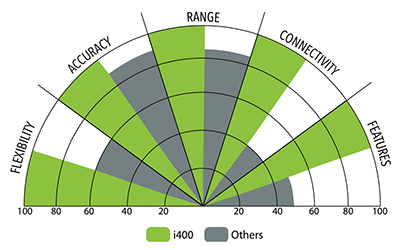

PERFORMANCE

UNBEATABLE ACCURACY - INCREDIBLE RANGE

Whether you’re delivering a bolus as small as 0.1 mL, or require a rapid continuous flow rate of 350 mL/min - the i400 has you covered.

Control speeds from 0.01 - 400 rpm [ ±0.5% FS ] with 0.01 rpm resolution. That’s a remarkable 40,000:1 turndown ratio!

Deliver dose amounts as low as 0.1 mL [ ±0.005 to ±0.015 mL based on tubing bore & scale integration ]. The i400 automatically controls delivery speeds based on stored calibration data, and doses efficiently and at the proper speed for your application.

SPECIFICATIONS

PERFORMANCE

| Speed Control | 0.01 - 400 rpm ( ±0.5% FS ) with 0.01 rpm resolution |

| Turndown Ratio | 40,000:1 |

| Flow Rates | 0.005 to 350 mL/min at 30 psi (2 bar) |

| Min. Dose Amount | 0.1 mL (±0.005 to ±0.015 mL based on tubing bore) |

| Tubing Size | 0.5/1.6mm to 4.8/1.6mm (bore/wall) |

COMMUNICATIONS

| Modbus RTU | RS-485 (half-duplex) Modbus App. Protocol Spec. v1.1a |

| Modbus TCP/IP | ODVA Conformance Tested |

| EtherNet/IP (Industrial) | ODVA Conformance Tested (ENetCT Ver A3.5) |

| FLUIDLINK.IO (Remote) | IEEE 802.3 10BASE-T (DHCP) |

| Weight Scale | USB (FTDI) RS-232 MT-SICS Protocol |

MECHANICAL

| Dimensions | (L x W x H) 10.1" x 4.1" x 9.0" (25.5 x 10.2 x 22.8 cm) |

| Weight | 1660 grams (3.67 pounds) |

| Touch Display | 272 x 480 TFT/LCD |

| Ingress Rating | IP33 / NEMA 2 - indoor use |

| Power Supply | 24 VDC / 3.0 Amp (from supplied transformer) |

| Transformer | Universal input: 100 - 240 VAC @ 50/60 Hz |

OPERATING CONDITIONS

| Temperature Range | +5 °C (+41 °F) to +40 °C (+104 °F) |

| Humidity | Up to 90% relative humidity non-condensing |

MATERIALS OF CONSTRUCTION

| Enclosure | TC-890 FR (wipe down 70% isopropyl alcohol) |

| Pump Head | IXEF PEI Grilamid PA 12 |

| Base Feet | Monsanto Santoprene (87 shore A) |

COMPLIANCE

| EMC Directive 2014/30/EU | BS EN 61326-1: 2013 |

| Low Voltage Directive (LVD) 2014/35/EU | BS EN 61010-1: 2010 |

| Machinery Directive 2006/42/EC | BS EN ISO 12100: 2010 |

| RoHS Directive | All components RoHS compliant (2011/65/EU) |

Warning: These products are not designed for use in, and should not be used for patient-connected applications. The information provided in this literature was reviewed for accuracy at the time of publication and is believed to be correct, however LAB DYNAMICS, Inc. accepts no liability for any errors it contains and reserves the right to alter specifications without notice. For current information contact LAB DYNAMICS directly. It is the users responsibility to ensure product suitability for use within their application.

SOFTWARE UPDATES

INVESTMENT PROTECTION - UNLIMITED FEATURES

The FLUIDLINK® line of products employ state-of-the-art functionality that’s years ahead of the competition - and it doesn't stop there! The i400 software (FLUIDLINK/OS) can be updated in the field, without needing to be returned to the factory. This powerful feature allows you to take advantage of newly added functionality, and brings future support for an emerging market of 3rd-party peripherals.

The i400 is already equipped for hardware interfacing with popular ultrasonic flow sensors, and other flow measurement add-ons. Support for these peripheral devices will be provided via periodic software updates, at no additional cost. We’re committed to continual product improvement and keeping your i400 on pace with your rapidly advancing industry needs.

The i400 is an easy choice for solving the most demanding fluid delivery challenges - today, and for years to come!

PHARMA 4.0 BUILT-IN

DESIGNED TO INTEGRATE WITH YOUR "SMART FACTORY"

Onboard predictive analytics allow i400 operators to proactively anticipate potential problems, before they happen.

For any automated device to be PHARMA 4.0 compatible it must be equipped with modern industrial connectivity in order to provide (publish) runtime and equipment health status. When used in conjunction with a PLC/DCS you'll have the option to implement monitoring and alarming for many lifetime and predictive maintenance indicators, to help prevent problems before they happen.

i400

LEADING COMPETITOR

Accumulated Runtime:

High Temp. Monitoring:

M2M Calibration Record Sharing:

Remote Monitoring & Control:

©2024 LAB DYNAMICS, ALL RIGHTS RESERVED. FLUIDLINK®, LABDYNAMICS®, AND THE RESPECTIVE LOGOS ARE TRADEMARKS OF LAB DYNAMICS